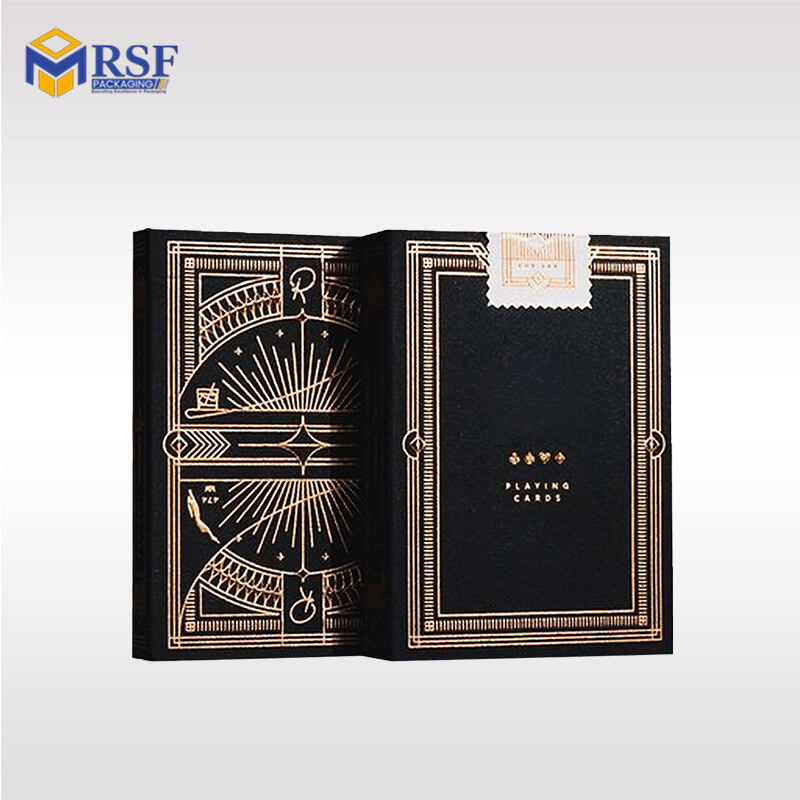

What is the first thing you notice while purchasing any of your everyday essentials? Obviously, it’s the packaging of the product. Product packaging is necessary to ensure product security as well as its safe transportation. So, a customer prefers choosing the right design and material for its product. For example, if you want the storage boxes for playing cards, you can get options like playing card boxes plastic, wooden, cardboard, etc. No industry can function without proper packaging services. Packaging companies are operating their businesses with huge success.

Qualities of a Good Packaging Company:

A variety of packaging materials manufacturers companies are providing services. So, choosing the right manufacturer is important to you. Here are the following considerations for choosing a packaging company for your business.

1- Quality packaging:

High-quality packaging should be your topmost priority while looking for a packaging company. The packaging industry is evolving due to technological advancement. They are continuously investing in upgrading their processes for better performance. Before choosing a company, make sure that they use effective processes and procedures. Further, ensure that they are following quality standards to manufacture packaging materials. Besides, manufacturing the packaging materials they should also have an efficient quality control system with regular inspections.

2- Customer service:

The companies that adhere to their core values provide top-notch customer services. Nowadays, customer service is a lot more than completing your order on time. A company that always try to improve their quality and bring new solutions to market can be good for your business success.

3- Packaging supplies:

Make sure the packaging company is well-versed in packaging supplies and materials. The packaging company should be able to provide cost-effective, easy alternatives, and good alternatives to routine packaging materials. A Vast range of packaging supplies enables them to assist their customers in a better way.

4- Capability:

People working in an organization determine its overall performance. Well-trained experts are the asset of any company. Before getting services from a packaging company, check if their staff s capable enough. The company’s staff should be aware of the regular practices followed while manufacturing product packaging. Besides this, they should be creative enough to come up with new ideas and solutions for your packaging needs.5- Package designing and functioning: Making the right package for a certain product is necessary. A package that fits your product size keeps the product intact as well as does branding for you is the ultimate preference of any customer. Companies provide services in making customized packages for your products according to your requirements. However, a creatively designed package with good aesthetic value will be of no use if it cannot function properly. Because a package that looks good but cannot make products safely reaching its customers isn’t worth spending. So, wisely choose the packaging company that provides reliable services in package designing as well it's functioning.6- Affordability is the most important aspect while choosing a packaging company. If the manufacturing cost of their product packages is more, it will add to the overall cost of your product. Unaffordable packaging can affect your product purchase because customers don’t prefer paying an extra amount for packaging.7- Flexibility: The service provider company should be flexible enough to accommodate last-minute changes. Last moment changes are unavoidable in any industry. And these changes are the major reason for conflict between product and package manufacturers. Such issues can disturb overall planning, working, and management. Therefore, choosing the right manufacturer that can manage challenges on your behalf is important to avoid unnecessary delays in your product delivery.8-Locality: The location of the packaging company is also very crucial. Because, if a company is far located from your product manufacturing unit, it will be quite risky. You have to invest in the transportation of your products before packaging and it can also damage your product. So, a packaging unit should be in the vicinity of your product manufacturing unit. It will not only save money but also your product will safely reach the packaging company.